Pyle Wing Nuts

A Pyle wing nut has two vertical half-oval-shaped wings on each side of the nut. The centre of one wing is open. This allows the nut to be further tightened by inserting a small bar in the hole and tighetening the nut. The Pyle nut was used to close the lid on locomotive headlamps.

|

| Pattern For Pyle National Wing Nut |

Our objective is to cast 6 Pyle wing nuts in bronze. This will be done using the lost-wax or investment casting process. The Pyle nut has been made out of wood and painted black. Our next step is to make a mold box which will be used to make a rubber mold of the part.

Once we have the rubber mold made, we will then be able to make wax castings/patterns of the Pyle nut.

The wax castings are then placed in a cylinder with wax sprues, gates and risers added to the wax castings. We then pour casting plaster into the cylinder. Once the plaster has hardened, we'll bake out the wax leaving a hollow mold that's the exact shape of our Pyle nuts. Melt some bronze, pour it into the mold and we should have a Pyle wing nut.

So let's get started with the first two steps - making a mold box and then the rubber mold.

1.0 Make The Mold Box

1.1 Cut - 2 pcs 4" wide x 3" high x 3/4" thick Baltic birch.

- 2 pcs 2 1/2" wide x 3" high x 3/4" thick Baltic birch.

- 1 pc 6" wide x 6" long x 3/4" thick Baltic birch.

1.2 Drill holes in the two pieces 4"x 3" at ends for #8 x 1 1/2" Robertson screws. Holes are located 3/4" from top and bottom and 3/8" in from the edge.

1.3 Loosely fit, align, assemble, clamp four pieces together in the shape of a box.

1.4

With the 4"x 3" pieces aligned, insert a 1/8" drill into the screw

holes and drill holes into the edges of the two pieces of 2 1/2" x 3"

about 3/4" deep. This will prevent the plies on the 2 1/2"x 3" pieces

from splitting when the pieces are screwed together. Repeat this step

for all other screw holes.

1.5 Screw the four pieces together so as to ensure a good square and level fit.

1.6 For ease of assembly, stamp the tops of each piece with identifying letters/numbers

1.7 - Mark the outline of the box on the 6"x 6" base plate. Drill four 1/8" holes from the top in the middle of each side.

1.8 On the bottom side, countersink the holes drilled in 1.7.

1.9

Align the box with the top of the base. Insert a 1/8" drill into the screw

holes and drill holes into the bottom edge of the four box pieces about 3/4" deep. This will prevent the plies on the box pieces

from splitting when the box is screwed to the base plate.

|

| The Bits-&-Pieces Of The Mold Box, Cut, Marked & Ready To Assemble |

|

| The Assembled Box & Base Plate Ready For Painting |

1.10 Disassemble the four side pieces. Paint the four side pieces and the 6"x 6" base plate with two coats of yellow paint.

1.11 Spray all pieces with two coats of clear lacquer. Dust talc powder onto all pieces after the lacquer has dried.

2.0 Making Bottom Half of Mold

2.1 Coat the insides of the side pieces and the top of the base with Vaseline. This will form a mold-release so that the rubber will easily release from the pattern and mold box. Re-assemble the box to the base with the #8 x 1 1/2" Robertston screws.

2.2 Get some modelling clay from Craft Store (Wallacks, Michael's, etc).

2.3 Place 1 1/2" of modelling clay in the bottom of the mold box. Press the pattern into the centre of the clay up to the parting line. Push the modelling clay flush against the parting line of the pattern with an X-Acto knife.

2.4 Roll a 3/8" piece of modelling clay. Cut a section of the clay in half along the radius/ centre line. Press the half-round of modelling clay into the mold box between the ends of the pattern and the sides of the mold box and shape in place. This will form a sprue and riser for the wax to enter the mold.

2.5 It may be necessary to fill any gaps between the sides of the mold box so that the RTV rubber doesn't leak from the box. Using the X-Acto knife, press modelling clay into these gaps.

2.6 Clean excess clay off the pattern and from the sides of the mold box. .

2.7 Make "registration marks" in the four corners of the modelling clay. Press the blunt end of a Sharpie marker into the modelling clay so as to create round depressions. The "registration marks" will help align the two halves of the rubber mold together.

2.9 Apply Vaseline, oil, or grease to the sprue, riser, and registration marks.

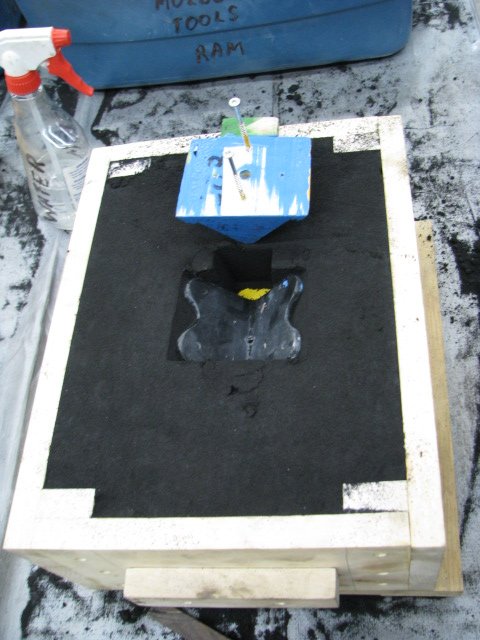

|

| The Mold Box & Pattern Ready For Pouring Rubber |

3.0 Pour Liquid Rubber Into The Mold Box

3.1 RTV rubber is a 2-part compound - the rubber which is in liquid format, and the catalyst which, when mixed with the rubber, will result in a solid rubber mass. There are two time elements to consider when using RTV rubber. The first is the "open time". This is the amount of time that the rubber can be worked with before it starts to harden. The second time element is "demold time". This is the amount of time required for the rubber to completely harden. The "open time" and "demold time" will depend upon the type and manufacturer. Refer to the manufacturer's instructions.

3.2 The "mix ratio" of rubber to catalyst will depend upon the type of rubber being used. Refer to the manufacturer's instructions.

3.3 We will be using

Alumilite Quick-Set Silicone Rubber. The "open time" is 30 minutes. The "demold time" is 8-18 hours. The "mix ratio" of rubber to to catalyst is 10-to-1 (10:1). That is, for every 100 grams of rubber, we will need 10 grams of catalyst.

3.4 Gather the tools and materials required to mix rubber:

| __ RTV Rubber Kit |

__ Weigh Scales |

| __ Paper Coffee Cups (2) |

__ Stir Sticks |

| __ Paper Towels |

__ Mold Box |

| __ Garbage Pail Close By |

__ Rubber Gloves |

|

| Tools & Materials Required To Mix RTV Rubber |

3.5 Sand one of the rounded ends of the stir sticks so that one end is flat. This will allow the stir stick to get into the edges of the paper coffee cup when mixing the rubber and catalyst. Using a utility knife, cut the paper coffee cups back to a height of about 2 1/2"- 3". This will facilitate the measuring, stirring, and pouring of the liquid rubber.

3.5 We need to calculate the volume/weight of rubber required so as to

provide 1" of rubber over the highest part of the pattern. Pour water

into the mold box until it is 1" above the top of the pattern. Pour the

water into a paper coffee cup and weigh the water. For this project, the weight of the water is 100 grams and thus we will need 100 grams of liquid RTV rubber.

3.6 Place a dry coffee cup on the weigh scale. Using the weight scale, pour 100 grams of rubber into the cup. Then pour the catalyst on top of the rubber until the scale reads 110 grams. This will give us the 10:1 ratio of rubber to catalyst.

3.7 Thoroughly mix the rubber and accelerant together for 3-4 minutes. Slowly pour the mixed rubber into the top of the mold box in a thin string so as to minimize air bubbles. DO NOT pour the rubber onto the top of the pattern.

3.8 If you have access to a vacuum pump, remove the air bubbles from the RTV rubber.

3.9 Let rubber harden for 24 hours.

4.0 Add Resin/Plastic "Mold Boards"

4.1 We will mix and pour a 1/4" layer of resin/ plastic on top of the rubber mold after cutting two registration marks into the hardened rubber. This will provide support and minimize deformation of the rubber mold when we join the two halves of the rubber mold together for pouring.

4.2 Plastic resins are a 2-part compound - the resin and the catalyst which are in liquid

format. The two, when mixed together, will result

in a solid plastic. There are two time elements to consider when

using resin. The first is the "open time". This is the amount of

time that the resin can be worked with before it starts to harden. The

second time element is "demold time". This is the amount of time

required for the resin to completely harden into a plastic. The "open time" and

"demold time" will depend upon the type and manufacturer. Refer to the

manufacturer's instructions.

3.3 We will be using

Alumilite Regular Castin Resin. The "open

time" is 90 seconds. We will have to move quickly to mix the resin and catalyst, and to pour the mix into the mold box. The "demold time" is 8-18 hours. The "mix ratio"

of resin to catalyst is 1-to-1 (1:1). That is, for every 100 grams of resin, we will need 100 grams of catalyst.

4.2 Using an X-Acto knife cut two V-shaped slots in the rubber mold next to the mold box. These will serve as registration marks for the plastic mold boards.

|

| Rubber Mold With Registration Marks Ready For Plastic "Mold Boards" |

4.4 We need to calculate the volume/weight of resin/plastic required so as to

provide 1/4"" of plastic over the top of the rubber. Pour water

into the mold box until it is 1/4" above the top of the rubber. Pour the

water into a paper coffee pot and weigh the water. For this project, the weight of the water is 50 grams. Since our mix ratio of Resin (Part A of our Alumilite) and Catalyst (Part B of our Alumilite) is 1:1 and we need a total of 50 grams of resin/catalyst mix, we will need 25 grams of resin and 25 grams of catalyst for this project.

4.7 Gather the materials and tools required to mix the resin::

| __ Plastic Resin Kit |

__ Weigh Scales |

| __ Paper Coffee Cups (3) |

__ Stir Sticks |

| __ Paper Towels |

__ Mold Box |

| __ Garbage Pail Close By |

__ Rubber Gloves |

4.8 Into one of the paper coffee cups, pour 25 grams of resin into one of the paper coffee cups. Call this cup "A". Into another paper coffee cup pour 25 grams of catalyst. Call this cup "B".

4.9 If you want, pour 3-4 drops of dye into cup "A" and stir until the mixture is a consistent colour. In our project we are going to use some brown dye.

4.10 Pour the contents of "A" into "B" and stir, making sure the stir stick reaches into the sides of the coffee cup.

4.11 Now pour the contents of "B" back into "A" and stir vigorously. This will make sure that we are mixing as much of the resin and catalyst together.

4.12 Pour the mixed contents of "A" slowly into the top of the mold box.

4.13 DO NOT try to pour any of the contents of "B" into the mold box. If dye has been added, the colour of "B" will be slightly different from the colour of "A" which will be very noticeable when the plastic sets in the mold box. It's around this time that the plastic starts to harden and, as you pour the contents of "B" into the mold box, air bubbles may start to appear.

|

| Plastic "Mold Boards" Just Poured |

4.14 Allow the resin to harden for 24 hours.

5.0 Demolding The Bottom Half Of the Rubber Mold

5.1 Remove the 6"x 6" mold board from the bottom of the mold box.

5.2 Unscrew and remove the four mold box side pieces.

5.3 Remove the modelling clay from the pattern and the rubber. DO NOT disturb the pattern in the rubber!

5.4 If necessary, brush off/wash away any clay remaining on the pattern and the rubber. Regrease the sides of the mold box and base with Vaseline, oil, or grease.

5.5 With the plastic mold board flush to the bottom of the mold board, fasten the mold box sides around the rubber mold, pattern, and plastic with the #8 Roberston screws. Screw the mold box to the 6"x 6" base with #8 Robertson screws.

5.6 Using a full round of 3/8" diameter modelling clay from 2.4, lay the round modelling clay in the half-round channels created in 2.4 between the ends of the patterns and the sides of the mold box. This will form a round sprue and riser for the wax to enter the mold.

5.7 Liberally brush Vaseline/oil over the exposed pattern, modelling clay, AND rubber.

5.8 Calculate, mix, and pour liquid rubber into the mold box following the instructions in Sectin 3.0. Let stand for 24 hours.

5.9 Using an X-Acto knife cut two V-shaped slots in the rubber mold next to the mold box. These will serve as registration marks for the plastic mold boards.

5.10 Add 1/4" resin/plastic "mold board" on top of the solid rubber following the instruction in Section 4 AFTER cutting the two registration marks in 5.9.

5.11 Remove the mold box and base plate from around the rubber mold.

5.12 Separate the two halves of the rubber mold. Remove the pattern and modelling clay from the rubber mold.

5.13 Carefully trim excess rubber from the sides of the mold.

5.14 Reassemble the two halves of the rubber mold aligning the halves with the registration marks. Tape the two halves together.

5.15 The rubber mold is now ready for pouring molten wax into the mold.

|

| The Finished Rubber Mold Ready For "Waxing" |

Next up, we

make some wax patterns and encase the patterns in some casting plaster.