In our previous post we chronicled one of the last days at Imbleau's Iron Foundry in Renfrew. Their last pour was on the following Tuesday, February 7th, 2012.

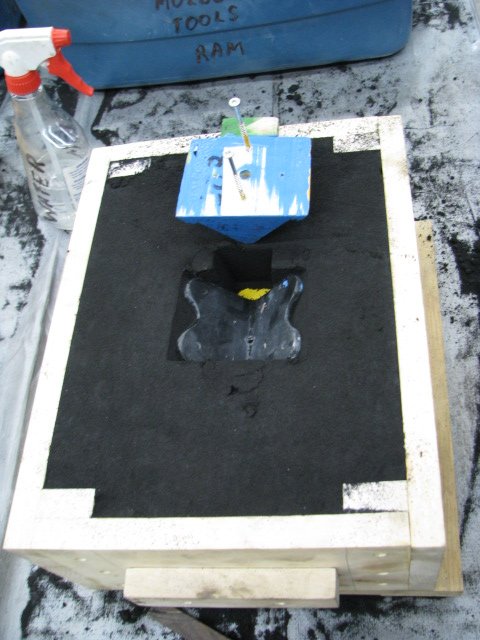

Our post prior to that were a set of instructions for making the green sand mold to pour the corner lantern brackets. Here's what the casting looked like about an hour after the molten iron had been poured into the mold at Imbleau's.

In case you're having difficulty seeing where the casting is, here's another photo with some added captions.

Here's a photo of another one of the brackets.

The steam is still rising from the green sand and the castings are still very, very hot. Don't touch!!

Just to recap on the process, we started off with an original casting that we had to duplicate. The hollows and holes were filled in by Jedi Master Ross producing the following pattern.

We next had to make a sand core to produce the holes and hollows that we had just filled up. So, Jedi Master Ross made a core box so that we could make sand cores. After a few modifications, we were able to start production of the sand cores.

Which, as you can visualize from the photo below, would nicely create the hollow that we need in the mold.

From there, we went on to make a dozen sand cores for our 12 castings - 6 for the flat lantern brackets and 6 for the corner lantern brackets.

One thing I learned with the first castings that I had done at Alumaloy was to test the sand cores and make sure that they fitted snugly into the green sand mold.

With the sand cores tested, we took our first batch up to Imbleau's for casting. Here's the pattern ready to go along with the 6 sand cores.

These were cast on Friday, January 27th. This is what the castings look like. The sprue, gate, and risers have been knocked off and you can still see the sand cores in the middle of the casting.

It was then that we discovered a challenge facing us. I had originally though that I could simply soak the casting in water and the sand core would disintegrate. So much for that idea! It took 15 minutes to sand-blast the sand core out of each casting. This is what the lot looks like with the sand cores removed and a bit more of the "flash" knocked off with a chipping hammer. Each one of those castings is a solid block of iron!

I was completely surprised that we were able to get things along this far! I was expecting an unrecognizable blob of iron.

Of course, the fun had only just started. First step was to drill out the holes for the mounting screws. While most of the 24 holes (6 castings x 4 holes per casting = 24 holes), there were 4 holes that wouldn't centre. A bit of grinding with a Dremel solved that problem.

Next up was to grind off the flash and the rough spots. One thing I discovered was that the sand cores were a bit loose in the green sand mold with the result that we had an extra bit of iron in the flash. Next time, we'll have to make the sand cores so that there is a tighter fit. Oh well, that's one lesson learned, eh!?

And this is what the final product looks like before Master Painter Charls gave them three coats of paint.

Not bad for a bunch of amateurs, eh!?

Monday, February 13, 2012

Thursday, February 2, 2012

A Day At Imbleau's Foundry - The Last Pour

I took a trip up to Renfrew today to pick up the patterns and castings that I had dropped off last Thursday and to see the pouring for the patterns that I had dropped off on Friday. Today was going to be a sad day as this was the last day that Imbleau's, after 160 years, would be pouring iron.

When I arrived, molten iron was running continuously from the foundry into the large crucible.

From there, each worker would place their smaller crucible on the ground. The foundryman would then tip the large crucible and red-hot molten iron would pour into their crucible.

A large crucible suspended on a travelling crane was placed near this part of the operation and the workers would empty the molten iron into the larger crucible. Three workers would then manouver the large crucible into the rows of large sand molds and align the lip of the crucible until it was exactly into the right position to pour the molten iron in the sprue of the sand mold. The crucible was slowly tipped forward and molten iron poured into the mold.

While the pouring was going on from the large crucible, other workers would get their hand-held crucible charged with molten iron and then walk Popeye-like with the handle of the crucible resting on the top of their leg over to the smaller sand molds and pour the red-hot molten iron into the top of the sprue.

When the iron appeared at the top of the riser, the mold was full of red-hot molten iron. The heat from the iron immediately turned the moist sand mold into a bath of steam. Throughout the foundry, steam was rising up into the air clouding the busy workers with their crucibles full of molten iron.

Through the rising steam I could barely make out the workers with the large crucible pouring the large sand castings.

Each worker seemed to automatically know what to do. There were no orders being shouted out by the foremen. They all worked in unison. When the large crucible was moved over to the furnace, a semi-circle of workers would form. As their small crucible was filled, they would move to the other side of the circle and pour it into the large crucible, taking their place at the end of the line once again.

When the large crucible was filled, three workers would move it away from the furnace and the other workers would then get their smaller crucibles filled with molten iron. One worker would go off into the south-eastern corner of the building; another worker would go off into the north-western part, each one followed by another worker who prepared the sand molds for pouring - lift the weight off of the molds that had been poured, shove a flask over the mold, then place the weight on top of the mold. Right behind him was the worker with the molten iron.

As the pour was coming to an end, the workers not pouring molten iron would up-end the sand molds to expose the iron castings. This would allow them to cool off faster. The molds were up-ended into rows where the green sand would be reconditioned for the next molding session.

I peered into the steaming cauldron of black sand seeing if I could see my castings. Aha!! There at the end of the row was one of my corner brackets.

Finally, the last of the sand molds was filled with molten iron. It was now time to pull the plug on the foundry to empty it of the molten and unmelted iron that was mixed in with the red-hot and unburnt coke. The wire rope was pulled, the furnace doors opened at the bottom and a large roar of flame shot up to the ceiling as the whole contents of the furnace dropped to the ground.

Anyone standing in front of that inferno would have been cooked to a crisp. The flame settled down and one of the workers hosed a steady flow of water onto the fiery mass.

Hard to understand the significance of that fiery flame as the contents of the furnace dropped to the ground. It signalled the end of an era that had lasted for more than 160 years.

When I arrived, molten iron was running continuously from the foundry into the large crucible.

From there, each worker would place their smaller crucible on the ground. The foundryman would then tip the large crucible and red-hot molten iron would pour into their crucible.

A large crucible suspended on a travelling crane was placed near this part of the operation and the workers would empty the molten iron into the larger crucible. Three workers would then manouver the large crucible into the rows of large sand molds and align the lip of the crucible until it was exactly into the right position to pour the molten iron in the sprue of the sand mold. The crucible was slowly tipped forward and molten iron poured into the mold.

While the pouring was going on from the large crucible, other workers would get their hand-held crucible charged with molten iron and then walk Popeye-like with the handle of the crucible resting on the top of their leg over to the smaller sand molds and pour the red-hot molten iron into the top of the sprue.

When the iron appeared at the top of the riser, the mold was full of red-hot molten iron. The heat from the iron immediately turned the moist sand mold into a bath of steam. Throughout the foundry, steam was rising up into the air clouding the busy workers with their crucibles full of molten iron.

Through the rising steam I could barely make out the workers with the large crucible pouring the large sand castings.

Each worker seemed to automatically know what to do. There were no orders being shouted out by the foremen. They all worked in unison. When the large crucible was moved over to the furnace, a semi-circle of workers would form. As their small crucible was filled, they would move to the other side of the circle and pour it into the large crucible, taking their place at the end of the line once again.

When the large crucible was filled, three workers would move it away from the furnace and the other workers would then get their smaller crucibles filled with molten iron. One worker would go off into the south-eastern corner of the building; another worker would go off into the north-western part, each one followed by another worker who prepared the sand molds for pouring - lift the weight off of the molds that had been poured, shove a flask over the mold, then place the weight on top of the mold. Right behind him was the worker with the molten iron.

As the pour was coming to an end, the workers not pouring molten iron would up-end the sand molds to expose the iron castings. This would allow them to cool off faster. The molds were up-ended into rows where the green sand would be reconditioned for the next molding session.

I peered into the steaming cauldron of black sand seeing if I could see my castings. Aha!! There at the end of the row was one of my corner brackets.

Finally, the last of the sand molds was filled with molten iron. It was now time to pull the plug on the foundry to empty it of the molten and unmelted iron that was mixed in with the red-hot and unburnt coke. The wire rope was pulled, the furnace doors opened at the bottom and a large roar of flame shot up to the ceiling as the whole contents of the furnace dropped to the ground.

Anyone standing in front of that inferno would have been cooked to a crisp. The flame settled down and one of the workers hosed a steady flow of water onto the fiery mass.

Hard to understand the significance of that fiery flame as the contents of the furnace dropped to the ground. It signalled the end of an era that had lasted for more than 160 years.

Monday, January 30, 2012

Marker Lantern Corner Brackets - Steps For Making Sand Molds

The pattern for the Marker Lantern Corner Brackets consists of the following elements:

The following are the suggested steps for creating the green sand mold:

1) Place the blue false pattern face down on the drag.

2) Place the black-and-yellow main pattern on top of the blue false pattern

3) Fill and ram, etc the drag with green sand.

4) Turn the drag over to expose the top of the blue false pattern

5) Using the two screws provided, remove the blue false pattern from the drag.

6) Depending on the height of the alignment pins in the drag, the clearances between the cope and the drag may be very close. In order to allow for a better clearance, cut a triangular piece out of the drag as shown in the photo below.

7) Place the unpainted wedge-shaped core print into the drag on top of the exposed yellow core print

8) Place the cope on the drag. Fill and ram, etc the cope with green sand.

9) Lift cope off of the drag. Cut in sprues, gates, risers, etc.

10) Rap and lift out the unpainted wedge-shaped core print.

11) Insert the blue wing-nut bolt into the threaded hole in the bottom of the yellow-and-black main pattern.

12) Rap and remove the yellow-and-black main pattern.

13) Finish off the rest of the mold, etc.

14) Insert the main sand core

15) Insert the wedge-shaped sand core

16 Finish off the rest of the mold, etc

- Main Pattern (painted black with yellow core prints)

- "False pattern" (painted blue)

- "False core print" (unpainted)

- Wing-nut bolt (painted blue)

- Main sand core (irregular shape)

- Wedge-shaped core print (Loose triangle-shaped piece of wood with the top chopped off)

The following are the suggested steps for creating the green sand mold:

1) Place the blue false pattern face down on the drag.

2) Place the black-and-yellow main pattern on top of the blue false pattern

3) Fill and ram, etc the drag with green sand.

4) Turn the drag over to expose the top of the blue false pattern

5) Using the two screws provided, remove the blue false pattern from the drag.

6) Depending on the height of the alignment pins in the drag, the clearances between the cope and the drag may be very close. In order to allow for a better clearance, cut a triangular piece out of the drag as shown in the photo below.

7) Place the unpainted wedge-shaped core print into the drag on top of the exposed yellow core print

8) Place the cope on the drag. Fill and ram, etc the cope with green sand.

9) Lift cope off of the drag. Cut in sprues, gates, risers, etc.

10) Rap and lift out the unpainted wedge-shaped core print.

11) Insert the blue wing-nut bolt into the threaded hole in the bottom of the yellow-and-black main pattern.

12) Rap and remove the yellow-and-black main pattern.

13) Finish off the rest of the mold, etc.

14) Insert the main sand core

15) Insert the wedge-shaped sand core

16 Finish off the rest of the mold, etc

Saturday, January 21, 2012

Marker Lantern Brackets - We Finish The Sand Cores

Well, after multitudinous fine tunings after casting each sand core, we finally got the last 4 to slip out of the core box "relatively" easy. There's still one minor major undercut which we've been trying to fix with some epoxy glue. We had a splinter shave off of the box that fills in the bottom core print. After 3 tries at fillng the shaving, we approached reasonable success. One last attempt. Only problem is we've got a dozen sand cores all cast which is exactly what we need.

However, if we decide to go into full-scale production, we'll fine tune them even more. Next up, we're going to test the sand cores in the green sand to make sure that they slide easily into the mold and rest where they should rest. But that's another story.

However, if we decide to go into full-scale production, we'll fine tune them even more. Next up, we're going to test the sand cores in the green sand to make sure that they slide easily into the mold and rest where they should rest. But that's another story.

Sunday, January 8, 2012

Marker Lantern Brackets - Now Here's A Challenge!

With a lot of old castings no longer available from the catalogue (they got deleted decades ago!), it gets a bit difficult to find them when you need them. The only alternative is to make some patterns and get them cast at a foundry. That's the problem we're facing with some brackets to hold marker lanterns that go on the end of a train - either on each side at the back end of the caboose or on the back end of the business car.

However, all is not lost! If you happen to have at least one casting, you can always use that casting to make a pattern. Such was the case at Bytown. We just happened to have two corner brackets and one "flat" bracket. Here's a close-up of one of the corner brackets.

It's kind of obvious that you just can't put it face-down in the flask, ram in some green sand, and extract the corner bracket so that we have a nice clean mold that we can then fill up with molten metal. No-sireee! Life is never that simple.

And when you look at this casting from the top, it becomes very obvious that this could get a little complicated, particularly when it comes time to making the sand core for this casting. We have a hole right through the middle of the casting and a slot that only goes partly down the front. The lantern simply slides into the slot and is held in place by the partial slot.

Fortunately, Jedi Master Ross, with his years of experience in using an existing casting for a pattern, knew what to do and quickly glued pieces of wood to the casting to make "core prints". Here's what he came up with for the flat casting (the corner casting is a bit more complex but we'll get into that one a little later).

If you compare this photo with the ones at the top of the post, you'll quickly see what he did. He glued a piece of wood into the slot, then a piece of wood on the top, and a piece of wood on the bottom. The piece of wood in the slot fills up the slot (obviously!). The top and bottom piece form the "core print" which will hold a sand core in place. It's the sand core that will replicate the "hollow" in the casting when the molten metal is poured into the green-sand mold.

So far, so good. But that's the easy part. We now come to the very, very difficult part - making the core box which we can use to make a sand core. If you take a peek back into the castings at the top, you will see that there are all kinds of lines and shapes going in all directions. First we have a slot that goes from the top of the casting to the bottom of the casting. Then we have a hollow cone that goes from the top all the way to the bottom of the casting. As the cone goes down from the top to the bottom the sides get narrower and narrower. Combine the full-length slot and the cone with the partial slot in the front and you get a very complex core box!

However, that problem had been solved by the Jedi Master at the same time that he modified the casting with the 3 pieces of wood. He had made the core box. There was only one problem. Actually, there were several but only one related to this casting. Because of the different lines going in all directions, the as-built sand core (which was a 2-piece "split mold") wouldn't release from the core box. The only way to get the sand core out of the core box was to break it all apart - which would defeat the original purpose of the sand core - n'est-ce pas!?

And so Ross handed the problem over to me to solve. It took 3 days of focused effort and 8 attempts at modifications, trial and error to start to solve the problem. Here's what the more recent disasters looked like before we finally were able to produce a decent sand core.

There were multiple problems with the core boxes and I didn't want to do anything drastic that would destroy the core box. Making another one would definitely be well beyond my capabilities. Finally, I took the plunge and ran the two halves of the split-core box through the band-saw to cut off a large chunk of wood that was holding the sand core in place. I then cut and screwed a piece of Baltic Birch plywood in place of the two chunks of wood that we cut out. I now had a core box that would release the sand core! At the same time, I cut another piece of Baltic Birch playwood to fit on to the other side of core box so that it would withstand the rigours of ramming core sand into the box. We were ready to start producing sand cores. Or so I thought.

I produced 8 sand cores (I numbered them "1" to "8"!). After Sand Core #2, I cut off half of the box that produces the bottom core print (after nailing it to the Baltic birch plywood) so that it would release easier. Each time I had to shave a bit-off-here and a bit-off-there. Finally, with Sand Core #8, I got my first perfect (well almost perfect) sand core. Here's what Sand Core #8 looked like with the pattern alongside. You can readily visualize the "hollow" that the sand core will make inside the mold and where the sand core is going to be kept in place by the hollows made by the yellow core prints.

Now it was time to go into mass production. I wanted to produce 12 sand cores and I only had one - Sand Core #8. I next gave all parts of the core box a good coat of yellow paint and one coat of spar varnish. Punched in some "witness letters" so that I could know what parts of the core box went where. So we were off to the races - ready to produce sand cores.

Yeah, right! Each time I produced a sand core, it wouldn't release easily out of the mold. I had to wiggle the two main halves of the core box and the sand core. There was usually a bit that broke off somewhere. Each time it was shave-a-bit-off-here and shave-a-bit-off-there. After another 8 tries, I ended up with 6 sand cores that were reasonably decent.

And here's the bits and pieces of the core box, along with Sand Core #1 - the second lot.

You can definitely see the complexity of the lines on the inside of the two halves of the split-mold. The lines go in multitudinous directions which result in hidden undercuts. that hold the sand core in the core box.

Short of a major re-manufacture, we'll stick with the wiggling routine as we only have 6 more sand cores to go.

Only 6 more to go and we're off to the iron foundry. But first we have to test the sand cores to make sure they fit into the green sand mold. That's up next.

However, all is not lost! If you happen to have at least one casting, you can always use that casting to make a pattern. Such was the case at Bytown. We just happened to have two corner brackets and one "flat" bracket. Here's a close-up of one of the corner brackets.

It's kind of obvious that you just can't put it face-down in the flask, ram in some green sand, and extract the corner bracket so that we have a nice clean mold that we can then fill up with molten metal. No-sireee! Life is never that simple.

And when you look at this casting from the top, it becomes very obvious that this could get a little complicated, particularly when it comes time to making the sand core for this casting. We have a hole right through the middle of the casting and a slot that only goes partly down the front. The lantern simply slides into the slot and is held in place by the partial slot.

Fortunately, Jedi Master Ross, with his years of experience in using an existing casting for a pattern, knew what to do and quickly glued pieces of wood to the casting to make "core prints". Here's what he came up with for the flat casting (the corner casting is a bit more complex but we'll get into that one a little later).

If you compare this photo with the ones at the top of the post, you'll quickly see what he did. He glued a piece of wood into the slot, then a piece of wood on the top, and a piece of wood on the bottom. The piece of wood in the slot fills up the slot (obviously!). The top and bottom piece form the "core print" which will hold a sand core in place. It's the sand core that will replicate the "hollow" in the casting when the molten metal is poured into the green-sand mold.

So far, so good. But that's the easy part. We now come to the very, very difficult part - making the core box which we can use to make a sand core. If you take a peek back into the castings at the top, you will see that there are all kinds of lines and shapes going in all directions. First we have a slot that goes from the top of the casting to the bottom of the casting. Then we have a hollow cone that goes from the top all the way to the bottom of the casting. As the cone goes down from the top to the bottom the sides get narrower and narrower. Combine the full-length slot and the cone with the partial slot in the front and you get a very complex core box!

However, that problem had been solved by the Jedi Master at the same time that he modified the casting with the 3 pieces of wood. He had made the core box. There was only one problem. Actually, there were several but only one related to this casting. Because of the different lines going in all directions, the as-built sand core (which was a 2-piece "split mold") wouldn't release from the core box. The only way to get the sand core out of the core box was to break it all apart - which would defeat the original purpose of the sand core - n'est-ce pas!?

And so Ross handed the problem over to me to solve. It took 3 days of focused effort and 8 attempts at modifications, trial and error to start to solve the problem. Here's what the more recent disasters looked like before we finally were able to produce a decent sand core.

There were multiple problems with the core boxes and I didn't want to do anything drastic that would destroy the core box. Making another one would definitely be well beyond my capabilities. Finally, I took the plunge and ran the two halves of the split-core box through the band-saw to cut off a large chunk of wood that was holding the sand core in place. I then cut and screwed a piece of Baltic Birch plywood in place of the two chunks of wood that we cut out. I now had a core box that would release the sand core! At the same time, I cut another piece of Baltic Birch playwood to fit on to the other side of core box so that it would withstand the rigours of ramming core sand into the box. We were ready to start producing sand cores. Or so I thought.

I produced 8 sand cores (I numbered them "1" to "8"!). After Sand Core #2, I cut off half of the box that produces the bottom core print (after nailing it to the Baltic birch plywood) so that it would release easier. Each time I had to shave a bit-off-here and a bit-off-there. Finally, with Sand Core #8, I got my first perfect (well almost perfect) sand core. Here's what Sand Core #8 looked like with the pattern alongside. You can readily visualize the "hollow" that the sand core will make inside the mold and where the sand core is going to be kept in place by the hollows made by the yellow core prints.

Now it was time to go into mass production. I wanted to produce 12 sand cores and I only had one - Sand Core #8. I next gave all parts of the core box a good coat of yellow paint and one coat of spar varnish. Punched in some "witness letters" so that I could know what parts of the core box went where. So we were off to the races - ready to produce sand cores.

Yeah, right! Each time I produced a sand core, it wouldn't release easily out of the mold. I had to wiggle the two main halves of the core box and the sand core. There was usually a bit that broke off somewhere. Each time it was shave-a-bit-off-here and shave-a-bit-off-there. After another 8 tries, I ended up with 6 sand cores that were reasonably decent.

And here's the bits and pieces of the core box, along with Sand Core #1 - the second lot.

You can definitely see the complexity of the lines on the inside of the two halves of the split-mold. The lines go in multitudinous directions which result in hidden undercuts. that hold the sand core in the core box.

Short of a major re-manufacture, we'll stick with the wiggling routine as we only have 6 more sand cores to go.

Only 6 more to go and we're off to the iron foundry. But first we have to test the sand cores to make sure they fit into the green sand mold. That's up next.

Subscribe to:

Posts (Atom)